Ajuda à prescrição e instalação de molas de pavimento.

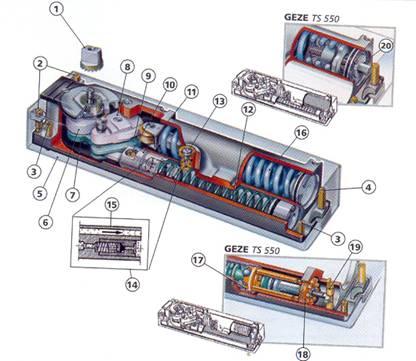

A mola de pavimento, assim como a sua irmã mais velha, a mola aérea, é hoje um complexo mecanismo, concebido para devolver a força que sobre uma mola helicoidal alojada no seu corpo é exercida quando abrimos uma porta fazendo girar o eixo que lhe serve de pivô.

No essencial a mola helicoidal vai, quando a porta é libertada, voltar à sua posição de repouso descomprimindo-se.

Para que essa descompressão possa fazer-se a uma velocidade controlada a mola helicoidal foi colocada dentro de uma câmara cilíndrica que, aquando da compressão da mola, se enche com um óleo especial que passa através de uma válvula franca e anti-retorno. Quando a mola pretende regressar à sua posição original ela pressiona o óleo dentro da câmara para que este lhe devolva o espaço ocupado. A saída do óleo é então controlada através de válvulas que regulam o seu fluxo, fazendo com que a mola descomprima mais depressa ou mais devagar, de acordo com a velocidade de fecho que se pretende para a porta.

1.Eixo intercambiável 2. Parafusos de fixação 3. Parafuso de regulação em altura 4. Parafuso de fixação 5. Caixa para chumbar ao cimento 6. Êmbolo de força de fecho 7. Êmbolo hidráulico 8. Mola oscilante 9. Pistão oscilante 10. Filtro de óleo 11. Pistão 12. Guia do pistão e da mola 13. Válvula regulável 14. Válvula de segurança 15. Canal de retorno do óleo 16. Mola de fecho 17. Coroa de esferas para controlo interno 18. Controlo de regulação 19. Controlo: em serviço/descanso 20. Regulação da força de fecho |

|

|---|

Para a escolha e prescrição de uma mola de pavimento devem ser tidos em conta os seguintes aspectos:

- O peso da porta, porque a mola de pavimento funciona como pivô de apoio, deve ser calculado para definição do tipo de mola a aplicar. Dependendo da mola eleita, podemos suportar portas até um peso máximo de 300 Kg.

- O tipo de eixo. O eixo da mola de pavimento é a sua ligação à porta. Assim é importante que a sua forma seja compatível com a forma dos encaixes previstos para a porta. Por defeito, as molas de pavimento de fabrico alemão são fornecidas com um eixo rectangular, já que os acessórios de fixação à porta fornecidos também têm aquela forma. No entanto, se a mola de pavimento vai ser utilizada em portas de vidro e os acessórios para as mesmas são de fabrico francês ou português, é possível que o eixo da mola tenha de ser trocado por outro com forma quadrada. A Triplo W disponibiliza eixos que se ajustam às necessidades do mercado.

3. A paragem na abertura. As molas de pavimento podem ser fornecidas com um ponto predefinido de paragem na abertura. Isto significa que sempre que a porta seja aberta até um ângulo de abertura “x”, esta se mantém nessa posição até receber um impulso no sentido do fecho. Os ângulos de paragem possíveis são: 85º, 90º, e 105º, dependendo do fabricante.

4. Os acessórios de ligação. Para que a mola possa funcionar precisa estar devidamente conectada ao elemento a controlar: A porta. Os acessórios dependem do tipo de porta e são, para uma porta batente em madeira, ferro ou alumínio

| a) O braço de apoio inferior | b) O pivot superior | c) As capas para os braços. |

|---|---|---|

|  | Estas capas são fornecidas à cor do alumínio, podendo ser posteriormente anodizadas ou lacadas de forma a esconder o ferro zincado dos braços. |

Para uma porta vaivém de madeira, ferro ou alumínio:

| d) O braço de apoio inferior | e) O pivot superior |

|---|---|

|

|

- A força da mola.

Esta é a força que a mola deve ter para poder fechar uma porta com uma determinada largura, massa e resistência eólica.

Como se determina? Sabemos, empiricamente, que algumas portas fecham perfeitamente quando são abertas e outras, com as mesmas dimensões e peso não fecham correctamente, quando controladas pelo mesmo equipamento.

De facto, quer a força natural do vento no local quer a acção de extractores de ar, nomeadamente em cozinhas industriais ou correntes de ar em caixas de escada de edifícios de habitação ou outros podem fazer com que uma mola calculada com a força suficiente para cumprir uma missão, se revele, depois de instalada, insuficiente.

Para resolver este problema os fabricantes criaram molas cuja força é regulável no local pelo instalador em função das necessidades.

Basicamente estas molas possuem um parafuso que, quando apertado ou desapertado vai comprimir ou descomprimir a mola helicoidal conferindo-lhe a força necessária em cada caso. Se não sabemos que força escolher, optamos molas com força regulável.

- Amortecimento na abertura. Sempre que uma porta é aberta violentamente (caminho de fuga) ou empurrada pelo vento no sentido da abertura, corre o risco de se partir contra a parede adjacente ou danificar algum dos seus elementos.

Para evitar esse efeito os fabricantes adicionaram outra característica aos seus equipamentos. Colocaram uma válvula no corpo da mola que funciona como o cinto de segurança dos automóveis, ou seja, quando a porta è empurrada suavemente ela não oferece qualquer resistência, mas quando empurrada violentamente ela trava o movimento de abertura.

- Cuidados a ter na instalação de molas de pavimento.

Uma boa mola de pavimento quando bem prescrita, ou seja, quando adequada à porta que vai controlar, deve funcionar durante muitos anos sem qualquer tipo de avaria.

Quando as molas são fabricadas segundo a norma EN 1154, devem ser capazes de abrir e fechar a porta, pelo menos, meio milhão de vezes.

Sabemos que na grande maioria dos casos isso não acontece.

Será porque a mola está mal regulada em termos de força ou velocidade de fecho?

Não!

Uma mola com as válvulas de regulação de velocidade todas abertas, fecha a porta de forma violenta, provocando a destruição da porta ou do seu aro, mas não da mola.

Será porque quando a porta está a ser fechada pela mola, os utilizadores têm a tendência para empurrar a porta ajudando a que feche mais depressa e, com isso, aumentam drasticamente a pressão do óleo no interior da mola danificando-a?

Não!

As molas de qualidade previnem esse erro de utilização, através de uma válvula de sobrepressão (14), que descarrega o óleo para uma antecâmara quando essa pressão aumenta desmesuradamente.

A razão fundamental para avaria prematura das molas de pavimento reside na deficiente instalação e tem a ver com o seu nivelamento em relação à porta.

O eixo da mola, que recebe e suporta o peso da porta, apoia-se num rolamento cónico de agulhas e deve estar perfeitamente alinhado com a porta na sua posição vertical.

Na grande maioria dos casos, o instalador não utiliza o nível para nivelar a mola no pavimento e, quando o faz, limita-se a nivelar a mola no sentido do comprimento (cerca de 27 cm) mas raramente possui ou utiliza um nível de pequenas dimensões para nivelar a mola no sentido da largura (cerca de 8 cm).

Porque o eixo não é flexível, está apoiado num rolamento de encosto na parte inferior e guiado noutro rolamento de gola na parte superior, se não estiver perpendicularmente alinhado com a porta, durante o processo de abertura e de fecho, acontece uma de duas coisas:

1.

O corpo da mola vai deslocar-se em círculo dentro da sua caixa quando não for bem apertado, procurando adaptar-se ao movimento da porta ou,

2.

O eixo desenhará um cone de revolução à medida que a porta se movimenta.

Este movimento tenderá a partir a camisa do rolamento de apoio, avaria que é denunciada pelo estalido fortemente audível de muitas das portas instaladas quando se abrem ou fecham.

Além desse efeito, o eixo tenderá também a tentar alargar o o-ring de vedação na parte superior, permitindo que o óleo se escape e produzindo o famoso “babar” das molas hidráulicas.

1º Cuidado a ter: Nivelar correctamente a mola de pavimento durante o seu assentamento.

As molas de pavimento são aplicadas, como o nome indica, no pavimento.

O processo de lavagem do chão com utilização dos mais variados produtos, normalmente cáusticos e fortemente oxidantes, vão destruindo o equipamento.

Apesar do corpo das molas ser de alumínio fundido e suficientemente espesso para resistir à corrosão existem alguns elementos que não são tão resistentes e que comunicam directamente com o interior da mola:

- As válvulas de regulação de velocidades.

Estas são de latão, de pequena dimensão e facilmente atacáveis pelos produtos fortemente agressivos das lavagens.

2º Cuidado a ter: Encher a caixa da mola com uma boa massa consistente, com elevada resistência a temperaturas elevadas e vedar a tampa da mola com silicone de boa qualidade.

Se cumpridos os dois preceitos anteriores, teremos uma mola bem instalada e com bom funcionamento garantido por muitos anos.

Resta-nos regular as válvulas que se encontram na parte superior da mola, antes de a fechar e isolar completamente, para que a velocidade de fecho e de golpe final sejam as que mais se adequam à situação da porta, de modo a garantir, não só uma vida longa mas também um funcionamento suave e firme.

Para qualquer dúvida relativa à utilização de molas de pavimento, consulte-nos, por favor.